China is one of the countries in the world that are most seriously affected by geological disasters and strengthening natural disaster prevention and control is related to the people's livelihood. Therefore, it is the top priority to fully implement the important statement on earthquake prevention and disaster reduction addressed by General Secretary Xi Jinping and establish an efficient and scientific geological disaster prevention and control system to realize the "modernization of disaster prevention and reduction".

Professor Chen Baoyi from the College of Construction Engineering of Jilin University leads a team which is working on the Subject 3- "Research on large-diameter drilling tools and miniaturization of construction machinery for catastrophic landslide prevention and control" of "R&D of Emergency Disposal and Rapid Treatment Technology for Large Landslides"-one of the projects under the National Key Research and Development Program. Recently this team announced important progress in its research. The SGQ400 large-diameter reverse circulation DTH hammer and Φ600mm drill bit with casing developed by the team were manufactured and assembled by Shanghai Jintai Engineering Machinery Co., Ltd.. FAT shows that the hammer and the bit work well. With an impact frequency of 21Hz, the single impact power of the hammer can be up to 2500J. The innovative variable diameter drilling bit with casing operates reliably and the indicators meet the design requirements.

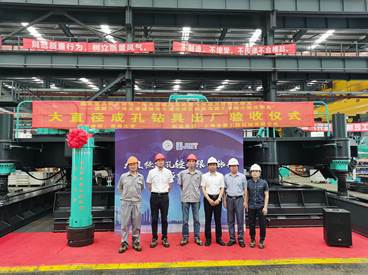

At the factory acceptance ceremony held on June 21, Li Daohua, the Chief Engineer of Shanghai Jintai Engineering Machinery Co., Ltd., announced that the large-diameter hole drilling tools developed by Jilin University had been tested in the factory, and the performance indicators of the drilling tools had reached the design requirements and were allowed to delivery. According to the schedule of R&D, the team entrusted Henan Yuzhong Geological Exploration Engineering Co., Ltd. to carry out the field drilling test. Now, the drilling tools are in transit to the project site in Jincheng, Shanxi Province for further tests. Prof. Chen Baoyi, together with his team members Associate Prof. Bo Kun, PhD students Cao Hongyu and He Wenbo, attended the factory acceptance ceremony.

Apart from efficient impacting and crushing of rocks, this set of drilling tools removes slags with reverse circulating air thanks to its pneumatic down to hole (DTH) hammer. That means it is able to protect the hole wall by following the casing while drilling rapidly in broken and collapse-prone strata, effectively keep the hole wall stable and reduce the construction disturbance of landslides. The tools feature high drilling efficiency, low power consumption and low environmental pollution. The successful implementation of this technology will not only significantly improve China’s capacity of drilling in complex strata, but also improve the prevention and rapid management capacity of China in mega-landslide disasters. It is of great significance for protecting life and property as well as effective prevention of mega-landslides.